Loud noises from an HVAC system can be symptomatic of underlying issues that may affect the system’s efficiency. Often, these sounds indicate mechanical troubles, such as loose fittings, worn bearings, or obstructions in the ductwork.

Not only do these hinder the system’s performance, yet it can also boost energy use while it fights to maintain temperature. Recognizing these noises early on and seeking professional assessment can avert more significant issues and help sustain the unit’s efficiency.

What are the common causes of loud HVAC noises, and how can they impact the efficiency of an AC system?

Loud HVAC noises often signal issues that can have an impact on how well an air conditioner runs. Common causes include:

- Loose Parts: Components such as screws, bolts, or fan blades can become loose over time, leading to rattling noises. These parts can cause vibrations and potentially damage other components, reducing system efficiency.

- Ductwork Expansion and Contraction: As air temperature changes, ductwork may expand or contract, creating popping or banging sounds. This doesn’t directly impact efficiency but may indicate poor insulation or duct issues that could affect overall system performance.

- Obstructed Air Flow: Blocked vents or a dirty air filter can create whistling or humming noises. Reduced airflow forces the AC to work harder to circulate air, decreasing efficiency and increasing energy costs.

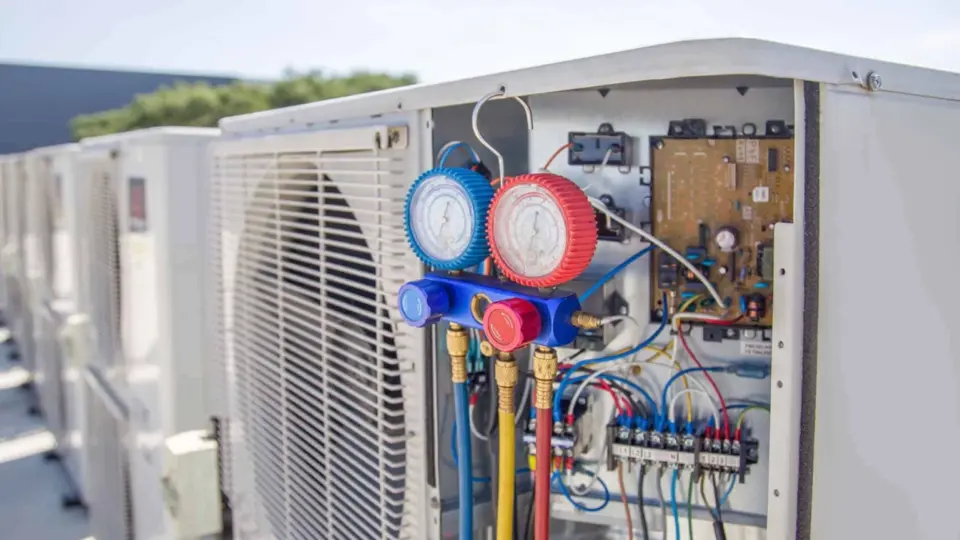

- Refrigerant Leaks: Hissing sounds often point to gas escapes from the refrigeration system. When the refrigerant level is too low, it might lead to a struggle to cool the air, significantly reducing efficiency and possibly leading to compressor failure.

- Compressor Issues: Noises like buzzing or grinding from the outdoor unit may indicate compressor problems. The compressor is the heart of the AC system; issues here can lead to decreased cooling efficiency and potentially costly repairs.

- Worn Bearings in the Fan Motor: Squealing or grinding sounds can be a sign that the bearings in the fan motor are failing. This can reduce the fan’s effectiveness, impacting air circulation and system efficiency.

These noises should not be ignored as they often indicate underlying issues leading to increased energy consumption, reduced cooling capacity, and premature system failure. Regular maintenance can detect and fix these problems early, maintaining the AC system’s efficiency and prolonging its lifespan.

Are there specific HVAC installation practices that can minimize or prevent noisy operation in air conditioning units?

Specific HVAC installation practices can significantly minimize or prevent noisy operation in air conditioning units. Adhering to these practices ensures the system operates efficiently and quietly:

- Proper Sizing: Ensuring the HVAC system is correctly sized for the space it will serve is crucial. An oversized or undersized system can lead to inefficient operation and excessive noise, as the unit may cycle on and off more frequently or strain to maintain desired temperatures.

- Strategic Placement: The location of both indoor and outdoor units affects noise levels. Outdoor units should be placed away from windows and neighboring properties to minimize disturbance. Indoors, units should be installed where noise will have the most negligible impact on living spaces.

- Use of Vibration Isolation Pads: Installing the outdoor compressor unit on vibration isolation pads can significantly reduce vibration-related noise that might otherwise resonate through the structure of the building.

- Flexible Duct Connections: Incorporating loose duct connections can help reduce noise from air movement and prevent it from transmitting through the ductwork system.

- Sound Attenuation Materials: Using insulation and sound-dampening materials around ductwork and in strategic locations can help minimize noise transmission by absorbing sound HVAC systems.

- Regular Maintenance: Proper installation must be followed by regular maintenance to ensure components remain in good condition and are not loose or worn, which can lead to increased noise levels.

- Correct Ductwork Design: Ensuring that ductwork is correctly sized and designed for optimal airflow helps prevent noise caused by high air velocity or turbulence within the ducts.

- Isolating Mechanical Rooms: Placing the equipment in a mechanically separated room with soundproofing measures can help contain the noise for larger HVAC systems.

- Professional Installation: Finally, installing the HVAC system by a qualified and experienced professional ensures that all components are correctly installed and calibrated, reducing the risk of noise issues.

Focusing on these installation practices makes it possible to significantly reduce the operational noise of HVAC systems, contributing to a quieter and more comfortable indoor environment.

How does addressing loud HVAC noises during installation contribute to the long-term efficiency and performance of the AC system?

Addressing loud noises during an HVAC installation is not merely about reducing auditory discomfort but also about safeguarding the system’s efficiency.

Noise often signifies underlying issues such as obstructed airflow, duct leakages, or mechanical problems—all potential harbingers of inefficient system operation. By proactively addressing these noise-related concerns, the installation process helps to ensure that the system operates smoothly from the start.

Better airflow means the system doesn’t have to work as hard to maintain desired temperatures, thereby conserving energy and reducing wear and tear on components, which extends the system’s service life.

What are the potential consequences of ignoring or neglecting noisy HVAC issues in terms of energy consumption and utility bills?

Ignoring or neglecting noisy HVAC issues can have several negative consequences, especially regarding energy consumption and utility bills. Here’s how:

- Increased Energy Consumption: Noises often indicate inefficiencies within the HVAC system, such as blocked air filters, leaks, or malfunctioning components. These inefficiencies force the system to work harder to maintain the desired indoor temperature, increasing energy consumption.

- Higher Utility Bills: As the system consumes more energy to compensate for its inefficiencies, homeowners will likely see a corresponding increase in utility bills. Over time, even minor issues can lead to significant extra costs.

- Reduced System Efficiency: Continuous operation under stress due to unresolved issues can reduce the overall efficiency of the HVAC system. This affects performance and leads to more frequent cooling and heating cycles, further driving up energy use and costs.

- Premature Wear and Tear: Neglected HVAC problems can cause components to wear out faster than expected. This premature wear and tear means parts will need to be replaced sooner, potentially resulting in costly repairs or even the need for a complete system replacement earlier than anticipated.

- Decreased Comfort: Inefficient HVAC operation can affect the system’s ability to maintain consistent temperatures throughout the home, leading to hot or cold spots and a generally less comfortable living environment.

- Environmental Impact: Higher energy consumption affects your utility bills and has a more considerable ecological impact. Increased energy use contributes to higher greenhouse gas emissions, affecting overall environmental sustainability.

- Potential Safety Risks: Although less directly related to energy consumption, some noises could indicate safety risks, such as electrical issues or a gas leak in furnaces, which could have severe consequences if ignored.

Addressing noisy HVAC issues promptly can help maintain system efficiency, reduce energy consumption, and keep utility bills in check while extending the system’s lifespan and ensuring a comfortable, safe home environment.

Silence HVAC Noise, Boost Efficiency!

At Elite Air & Heat, LLC, we understand the importance of a quiet, efficient HVAC system. Don’t let disruptive noises rob you of comfort and drive up energy costs. Our skilled technicians are at your service to diagnose and resolve any HVAC issues swiftly, ensuring optimal performance and durability.

Embrace a tranquil home atmosphere and enjoy savings on your energy bills. Contact us today to silence your HVAC and enhance efficiency.